Transforming Industrial Robotics with Edge AI Computing for Smarter Automation

Robots are now a key part of industries worldwide, helping to make operations faster, more accurate, and less reliant on manual labor. From building cars to organizing warehouses, robots handle complex and repetitive tasks with high precision and speed. A forward-thinking AI robotics and software company is focused on making industrial robots smarter and easier to use. By creating a system that combines a streamlined dataflow and an easy-to-use operating platform, they aim to make robots more adaptable and cost-effective. Their technology simplifies the programming process, allowing robots to adjust to new tasks on their own, cutting down the need for manual reprogramming.

This case study shows how this AI robotics company uses C&T Solution’s industrial computing systems to improve the performance and reliability of their AI-powered robots, ensuring they meet the demands of modern automation.

Challenge:

Traditional PLC systems struggle with:- Handling advanced AI-driven tasks like object detection and motion planning.

- Adapting to real-time analytics in dynamic environments.

- Compatibility across different robotics platforms due to brand dependency.

Solution:

- Intel 13th Gen CPUs, NVIDIA A5000 GPUs, and DDR5 RAM for high-performance AI processing.

- Support for advanced perception, motion planning, and control beyond PLC limitations.

- Automation-ready I/O (DIO, CAN Bus, COM) with a user-friendly design for industrial use.

Benefits:

- AI-Enhanced Robotics: Seamless execution of resource-intensive tasks.

- Real-Time Data Processing: Improved precision and motion planning.

- Rugged Reliability: Built for harsh environments with predictive maintenance for reduced downtime.

Company Background

This AI robotics and software company focuses on advanced automation systems, integrating AI to make robots smarter and more responsive to their surroundings. Using artificial intelligence and machine learning, the company develops solutions that help robots learn, adapt, and perform complex tasks without constant manual reprogramming, boosting efficiency and reducing human effort.

The company emphasizes rugged, industrial-grade edge AI computing solutions that handle heavy processing demands in tough environments. Its cloud-based platform enables manufacturers to scale robotics applications across industries such as manufacturing and logistics. By working with industry leaders and pushing the boundaries of automation, the company is transforming how robots interact with the real world, creating smarter and more efficient systems for industrial use.

The Challenge

The robotics solution provider needed a computing infrastructure capable of real-time processing for complex tasks like manipulation, perception, and pathfinding. These tasks require powerful edge AI performance, low latency, and high reliability to function in demanding industrial environments with harsh conditions and unstable power supplies. Traditional computing systems based on outdated architectures could not meet these requirements.

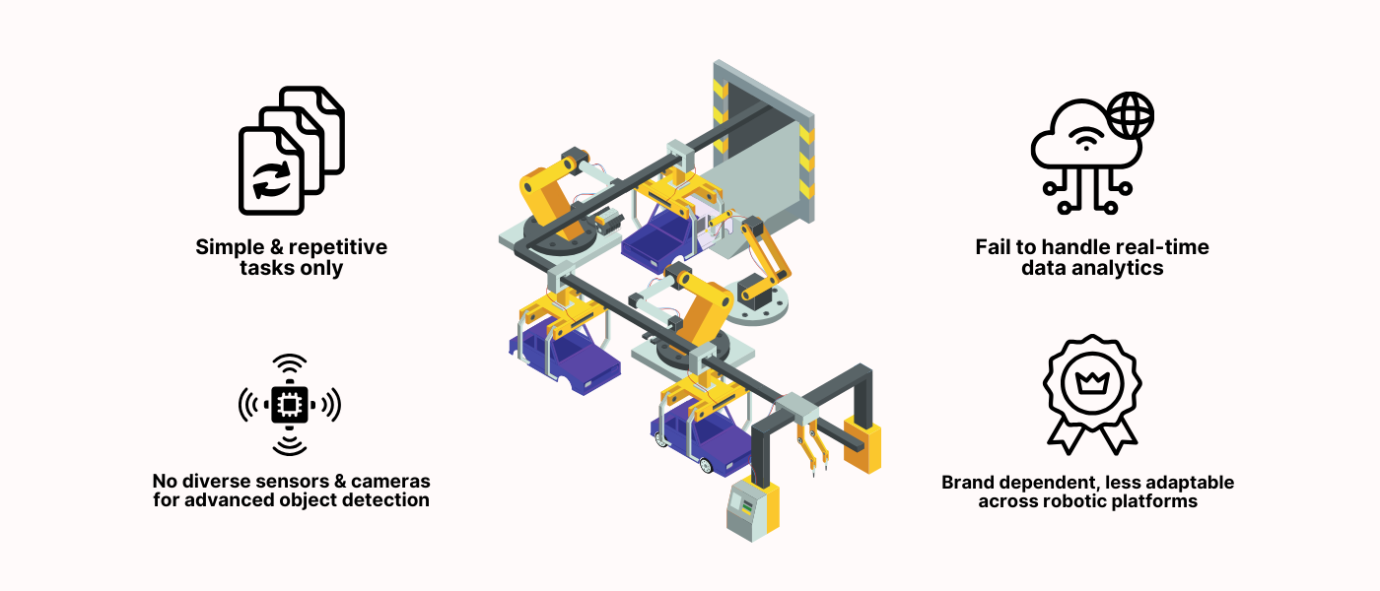

The Drawbacks of Using PLCs in Industrial Settings

PLC-based workflows, while suitable for basic repetitive tasks, lack the flexibility needed for advanced robotics. Tasks such as object detection and pose estimation, which involve integrating multiple sensors and cameras, exceed the precision capabilities of PLCs. Additionally, PLCs are not equipped for advanced motion planning, which can result in inefficiencies, collisions, and difficulty adapting to dynamic environments.

Real-time data analytics, critical for quick responses to changing conditions, often overwhelms the processing limits of PLCs, causing delays and performance issues. Furthermore, their brand-specific nature limits compatibility across robotic platforms. To overcome these challenges, the company required a robust AI-driven edge computing solution designed for the speed, precision, and adaptability demanded by modern robotics applications.

Read more about PLCs vs Industrial PCs

The Solution: VCO-6000-RPL Series Machine Vision Computer

To address its challenges, the company partnered with C&T Solution and implemented the VCO-6000-RPL industrial machine vision computer. Designed for tough environments, the VCO-6000-RPL enhanced the company’s AI robotics solutions with these key features:

High-Performance AI Processing

Traditional PLCs and older PCs often experience “throttling” during robotics motion planning and perception, leading to operational failures. The VCO-6000-RPL, powered by NVIDIA A5000 GPUs, PCIe Gen 4, and 13th Gen Intel Core CPUs, eliminates these issues with advanced AI acceleration at the edge. This setup allows robots to run machine learning algorithms directly on-site, reducing reliance on cloud processing and significantly lowering latency for critical operations.

Rugged Reliability for Industrial Environments

Built for demanding factory settings, the VCO-6000-RPL operates reliably in extreme conditions, withstanding temperatures from –25 to 70°C, shocks, vibrations, and dusty environments. It complies with military standard 810G and includes a secure GPU bracket to ensure stable performance in high-stress situations, making it ideal for industrial robotics deployments.

Flexible PCIe Expansion for High-Speed Networks

The VCO-6000-RPL supports up to four PCIe Gen 4 slots, offering the flexibility needed for expanded connectivity and processing. This allows seamless integration with SFP+ fiber cards and Intel-based chips that support the EtherCAT protocol, enabling precise, low-latency control for real-time robotic operations.

The Benefits

By incorporating C&T Solution’s advanced edge AI computing systems, the robotics company achieved notable advancements in their robotic solutions:

- Improved Reliability and Uptime: The rugged design of the VCO-6000-RPL reduced robot breakdowns, increasing uptime and boosting overall operational efficiency.

- Enhanced AI Functionality: The integration of edge AI technology enabled robots to better understand and adapt to their surroundings, making them more effective in dynamic environments like factories and warehouses.

With C&T’s durable edge AI computing solutions, the company transformed its robotics capabilities, adding intelligence, reliability, and real-time processing power to its systems. This collaboration not only optimized operations but also positioned the company as a leader in robotics innovation, equipping them to handle complex automation challenges with ease.