AMRs vs. AGVs: Which Industrial Computer is Right for You?

Why Industrial Computers are Key for AGV & AMR Operations?

Industrial computers play a crucial role in the smooth operation of Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs). These specialized computers help avoid the lag that comes with regular cloud computing by processing tasks right on the spot. This is vital since these robots need to respond instantly to their environment to work effectively. By handling data locally, these computers help AGVs and AMRs function in real-time, use less internet bandwidth, and improve safety and tracking.

While standard desktop computers can handle some of these tasks, they aren't suitable for the demanding settings in which AGVs and AMRs work. Industrial computers, on the other hand, are built to withstand tough conditions and can run around the clock without breaks or maintenance, making them ideal for AGV and AMR use.

Benefits of Industrial Computers for AGV & AMR Deployments

Real-time Edge AI Processing

Traditional cloud computing can slow things down with delays, rely too much on stable internet connections, and use up a lot of bandwidth. For automated guided vehicles (AGVs) and autonomous mobile robots (AMRs), which need quick reactions, these delays are a big problem. They need immediate data to make smart decisions. AGVs and AMRs can work more efficiently and smoothly using industrial computers for real-time edge AI processing.

These industrial computers are installed right where AGVs and AMRs operate, either on-site or inside the vehicles, to minimize delays and reduce dependence on cloud-based systems. They use a mix of different computing methods, including special hardware accelerators, to combine data from various sensors, handle and analyze immediate data needs, and quickly save this data for later use. By incorporating tough, ready-for-anything edge computing into AGVs and AMRs, these systems ensure they're always up and running, making fast, informed decisions that boost overall performance.

Connectivity for AGVs and AMRs

Industrial computers are specially made to support the connectivity needs of AGVs and AMRs. They are equipped to handle both current and older types of connections, ensuring they work well with a wide range of IoT sensors, cameras, and devices commonly used in these systems. Typically, these computers include specific inputs and outputs tailored for automation and robotics. For example, they have DIO for programmable switches, CAN Bus for live vehicle data, and an Out-of-band (OOB) module for managing the system remotely. This setup helps maintain seamless operation and connectivity in AGV and AMR deployments.

Scalable and Flexible Customization

Not every deployment of AGVs and AMRs requires the same setup. Each one might need different levels of processing power, types of IoT connectivity, and other specific features. To cater to these varying requirements, C&T offers three levels of performance options, from basic setups to advanced systems that are certified for high performance. A key feature of C&T is its support for EDGEBoost I/O technology. This technology includes modules that offer versatile connection options such as M12 connectors, Power over Ethernet (PoE), 5G wireless capabilities, and M.2 performance enhancement, ensuring that all types of deployment needs are met.

X86 Super Rugged Computers (RCO Series)

NVIDIA Jetson AI Edge Computers (JCO Series)

Top Safety Standards for Industrial Computers

Industrial computers are integral to critical operations involving AGVs and AMRs, where reliability and safety are paramount. A failure in the AGV system could not only cause significant operational downtime but also pose serious risks on-site. Manufacturers like C&T recognize the importance of consistent reliability and commit to rigorous testing and validation by Nationally Recognized Third-Party Laboratories (NRTLs). Achieving a UL-Listed certification means that the product has passed detailed inspections and meets all its safety claims. This certification allows users to confidently verify the safety of their industrial computers, ensuring they can depend on their AGV and AMR systems without worry.

Fanless & Cableless Industrial Computers

Industrial computers are designed without fans or cables, enhancing their durability and reliability in tough environments. Fans often fail and can be a weak spot in the system, but with a fanless design using passive cooling, the computer's chassis is completely sealed. This not only supports a broad range of operating temperatures but also provides resistance to shocks and vibrations, and can handle varying power inputs. Additionally, by eliminating cables, these computers reduce the risk of failures due to cable damage or accidental disconnections throughout their operational life. This design is crucial for maintaining consistent and reliable performance in demanding settings.

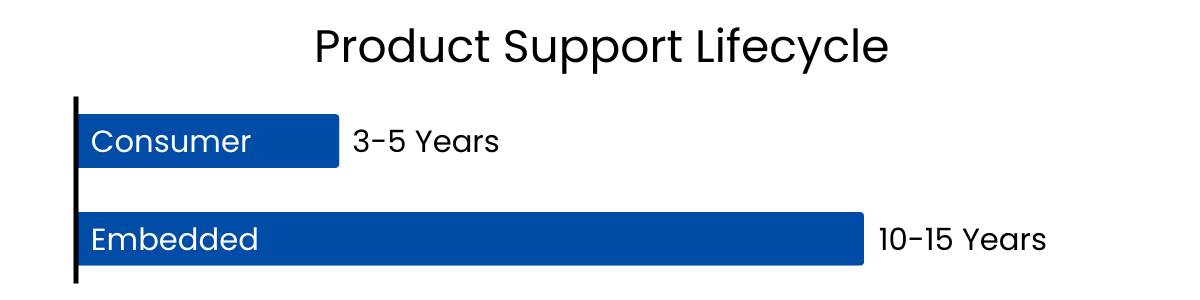

Industrial-Grade Longevity and Embedded Lifecycle Support

In rugged edge computing, manufacturers such as C&T integrate specialized hardware and software to ensure prolonged support and reliability for industrial computing solutions. AGV and AMR integrators often partner with these manufacturers due to their robust lifecycle support and expertise in the latest computing technologies that optimize both performance and energy efficiency. This approach helps avoid the need for updates and changes due to products reaching the end of their lifecycle, which can otherwise lead to critical downtime and delays. Such partnerships are essential for maintaining continuous operation without the disruption of having to frequently revise deployment strategies.

In the case of rugged edge computing manufacturers, like C&T, our engineers integrate these embedded-centric hardware and software into their industrial computing solutions for prolonged support capabilities and embedded reliability. AGV and AMR integrators typically establish partnerships with edge computing manufacturers because of their accommodating lifecycle support and expertise on the latest computing architectures that balance performance and power efficiency. This avoids the need to make deployment revisions due to end-of-life product updates that can cause mission-critical downtime and delays.

Now that you know the vital role industrial computers have in supporting AGV and AMR operations, consider reaching out to an expert at C&T. We can help you create the most efficient and optimized computing solution for your AGV/AMR needs!