Rugged IoT Surveillance: C&T's Fanless Mini PCs for Oil and Gas Operations

The oil and gas industry requires durable, high-performance computing solutions to withstand extreme environmental conditions, including severe temperatures, vibrations, and exposure to dust and debris. This case study highlights how a leading energy exploration company implemented C&T’s RCO-1000-EHL Fanless Mini Computer to improve real-time surveillance at remote well sites. By addressing challenges like sensor and camera integration, reliable operation in isolated locations, and uninterrupted data processing, the RCO-1000-EHL helped enhance monitoring efficiency in one of the world’s most demanding industries.

Challenge:

- Surviving Harsh Environments – Systems needed to operate reliably 24/7 in extreme temperatures, high vibrations, and remote conditions.

- Limited Space for Hardware – Compact and space-efficient computing was essential for confined control rooms and remote setups.

- Seamless Real-Time Integration – The solution had to support edge processing, surveillance, and IIoT device connectivity without delays.

- Scalability for Growing Data Needs – The increasing number of IP cameras and sensors required efficient storage and management solutions.

- Effortless Installation – DIN rail mounting was needed for quick and secure deployment across multiple locations.

Solution:

- Reliable 24/7 Performance – Low-power efficiency (12W TDP) ensures stable, round-the-clock operation in mission-critical applications.

- Extreme Durability – Wide temperature tolerance (-40°C to 70°C) and MIL-STD-810G compliance guarantee long-term reliability in harsh conditions.

- Fanless Thermal Design – Advanced passive cooling prevents dust accumulation and reduces maintenance in remote locations.

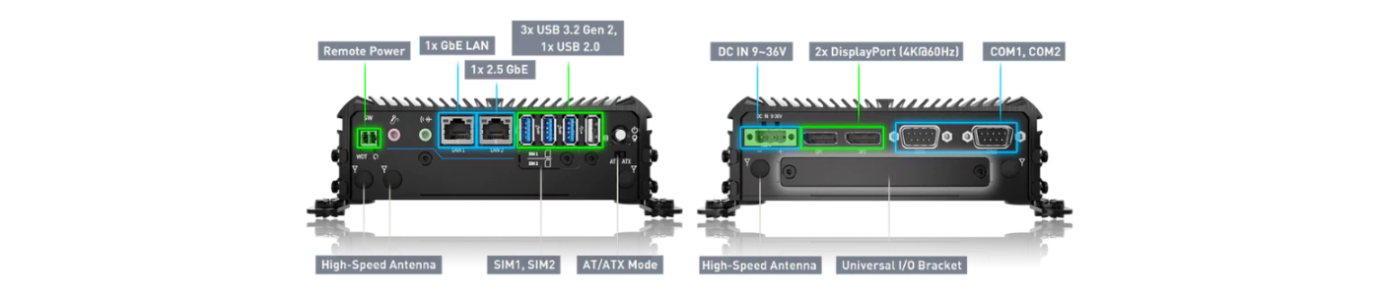

- Seamless Connectivity – Rich I/O ports (USB 3.2, COM) allow effortless integration with IP cameras, IIoT sensors, and telemetry systems.

- Scalable Data Management – Supports up to 1TB of storage and wide-temp DDR4 RAM, ensuring smooth high-resolution video and sensor data processing.

- Easy Deployment & Customization – DIN rail mounting and a modular I/O design simplify installation and system expansion.

Benefits:

- Proactive sales & engineering support for faster time-to-market

- ISO certified facility

Company Overview

Founded in 1999, this oil and gas exploration and production company specializes in methane detection, environmental monitoring, and operational efficiency. Operating in challenging environments across multiple regions, the company uses IoT technology and rugged computing systems to improve safety, efficiency, and reliability. With a strong focus on sustainability and innovation, it integrates smart monitoring solutions and scalable data technologies to support modern energy exploration, ensuring long-term resilience and performance in the industry.

The Challenge

Working in the harsh oil and gas sector, the company needed a rugged and reliable surveillance system for remote and extreme environments. Their previous computing solutions failed under tough conditions, leading to downtime and costly repairs. They also faced challenges with real-time data processing and system integration, which reduced operational efficiency. To ensure smooth and safe operations, they required a durable, compact, and scalable computing solution.

Durability in Harsh Environments

The company operates in areas with extreme temperatures, strong vibrations, and unpredictable weather conditions. For example, during the 2021 Texas Freeze, many systems failed due to the cold, even though temperatures did not reach -40°C. This event highlighted the need for industrial-grade computing that can operate 24/7, ensuring reliability, safety, and minimal downtime.

Compact and Space-Efficient Design

Oil and gas sites have limited space, especially in control rooms and remote setups. The company needed small yet powerful computing systems that fit in tight spaces without sacrificing performance. A fanless design with effective heat management was crucial for long-term stability and reliability.

Real-Time Integration for Surveillance

The company relied on IP cameras and IIoT sensors to monitor operations but struggled with poor connectivity and slow response times. Their previous systems lacked the necessary I/O ports to support real-time video feeds and sensor data processing. A high-performance solution with flexible connectivity was needed to improve monitoring accuracy and decision-making.

Scalability for Expanding Data Needs

As the number of cameras and sensors increased, the company had to manage large volumes of high-resolution video and sensor data. They required a powerful, scalable computing system that could handle growing data loads efficiently without slowdowns.

Easy Installation and Integration

With operations spread across multiple locations, the company needed a system that was easy to install and deploy. DIN rail mounting was a key requirement, allowing quick integration into existing enclosures, reducing setup time, and ensuring seamless deployment across different sites.

The Solution: RCO-1000-EHL Ultra-Rugged Fanless Mini PC

To overcome these challenges, C&T introduced the RCO-1000-EHL Fanless Mini Computer, a rugged computing solution built for demanding industrial environments. With wide-temperature support, strong I/O connectivity, and a compact form factor, this system provides reliable, real-time surveillance in extreme conditions. Powered by the Intel® Atom® x6425E processor and featuring a modular design, the RCO-1000-EHL is engineered to meet the needs of modern industrial operations.How the RCO-1000-EHL Solved the Company’s Challenges

Reliable 24/7 Performance

Built for continuous operation, the RCO-1000-EHL delivers energy-efficient performance for mission-critical applications like real-time monitoring and surveillance. Its low-power consumption reduces downtime and operational risks, ensuring system reliability in harsh environments.

Advanced Thermal Management

With a fanless design and industrial-grade materials, the RCO-1000-EHL uses passive cooling to keep operations stable in extreme temperatures and remote locations. By eliminating moving parts, it reduces maintenance needs and improves long-term durability, making it ideal for isolated installations with limited access for repairs.

Seamless Integration with Surveillance & IIoT Devices

Equipped with USB 3.2 and COM ports, the RCO-1000-EHL easily connects to IP cameras, IIoT sensors, and telemetry systems. This allows for real-time video streaming and environmental monitoring, improving decision-making and operational efficiency.

Efficient Data Processing & Storage

With up to 1TB of storage and wide-temperature DDR4 RAM, the RCO-1000-EHL can handle high-resolution video streams and large amounts of surveillance data without interruptions. Its robust storage and memory capabilities ensure smooth, long-term operation, even as data volumes grow.

Easy Installation & Customization

A key feature of the RCO-1000-EHL is its DIN rail mounting, allowing for quick, secure installation in different industrial setups. Its modular design makes customization easy, reducing installation time and system complexity.

The Benefits

C&T, in collaboration with its trusted partner located in Greater Los Angeles, delivered a rugged edge computing solution that not only met all operational challenges but also provided additional advantages through technical expertise, efficient manufacturing, and customer-first support.

Fast Deployment with Proactive Sales & Engineering Support

With dedicated sales and supply chain teams, C&T and its partner ensure fast and seamless deployment of computing solutions. Their proactive support helps businesses meet time-sensitive operational needs, ensuring that critical systems are up and running without delays.

ISO-Certified Manufacturing for Quality & Reliability

C&T’s partner operates in an ISO 13485:2016, ISO 9001:2015, and ISO 14001:2015-certified facility, guaranteeing high-quality, reliable, and environmentally responsible production. Strategically based in Greater Los Angeles, the streamlined supply chain enables on-time delivery while expert engineering and sales teams provide customized solutions and industry-leading support to ensure success in demanding environments.

Contact us to consult with our industrial technical experts.