Revolutionizing Defect Inspection with AI-Driven Machine Vision PCs and Touch Monitors

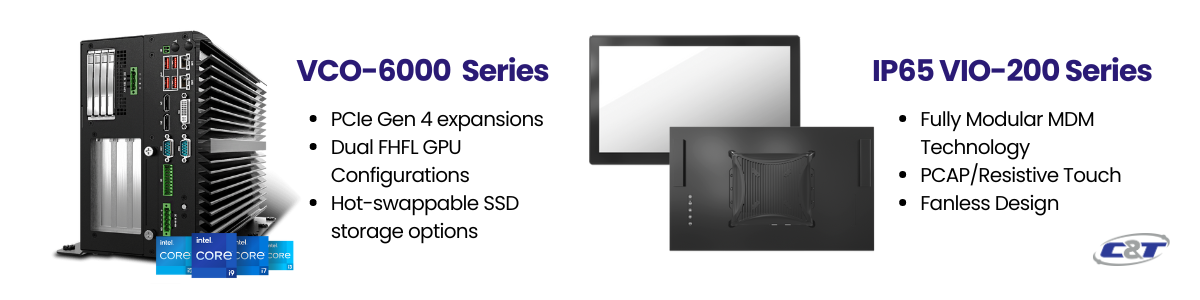

In the competitive realm of industrial automation, the fusion of high compute power and cutting-edge technology is essential for staying ahead. This case study explores how an innovative AI technology company leverages C&T's machine vision systems VCO-6000 series and IP65 VIO Modular Panel Touchscreen Monitor to enhance inspection processes, minimize production risks, and maintain a competitive edge.

Challenge:

- Required a robust machine vision computer for edge AI vision software.

- Needed durability for harsh warehouse conditions and seamless assembly line integration.

- Required a rugged touch panel monitor as a human-machine interface (HMI).

- Specifications included support for a full-size GPU, expansion slots, and a 10GB LAN card.

Solution:

- Implemented C&T's VCO-6000 Series with Intel® Core™ i7-9700TE and NVIDIA RTX A4000.

- Employed C&T's VIO Series - Rugged IP65 Modular Panel Touchscreen Monitor.

- Leveraged over 10+ years of C&T’s industrial-grade computing expertise.

Benefit:

- Customized computing needs met with PCIe expansion for intelligent vision.

- Modular VIO Series seamlessly integrated with the MX100H module for extended I/Os.

- Enhanced operational efficiency and reduced manufacturing errors with high-speed cameras.

- Secure and stable integration and installation in harsh environments.

- Benefited from dedicated guidance, testing, and support from C&T’s teams.

- Established a robust partnership for continuous support and future projects.

This approach has enhanced overall production quality and efficiency, setting a standard for future machine vision advancements.

The Company

In the dynamic field of machine vision systems, the continual advancement of computing power and cutting-edge features is essential to prevent hardware solutions from becoming outdated. This customer, an AI technology company, develops machine vision solutions designed to optimize inspection processes, decrease production risks, and more. High-resolution imaging, seamless integration with artificial intelligence, and sturdy designs are key factors that elevate their offerings in the marketplace.

The Challenge

The customer needed a machine vision computer robust enough to efficiently run their software, seamlessly integrate with high-speed cameras, and operate reliably in a demanding industrial environment. Their specifications called for a high-performance processor with over six cores and advanced graphics support. Additionally, they required front accessible I/O for straightforward integration into their assembly line and a 10GB Ethernet card for effective device communication. The system also had to be exceptionally durable to withstand dusty conditions without sacrificing any performance criteria, and it needed a wide input power range to align with their power supply needs. Recognizing these complex needs, the customer partnered with C&T, leveraging their specialized expertise in machine vision technology.

The Solution

C&T suggested their VCO-6000 series, a Machine Vision Computer powered by a 9th Gen Intel® Core™ Processor and equipped with PCIe expansion options. This choice was aimed at enhancing reliability and avoiding the complexities of a custom solution, thereby preventing potential downtime for the customer. Also, during the testing phase of the project, the customer identified the need for an HMI to work seamlessly with the Machine Vision Computer in their challenging industrial setting. C&T was able to meet this need effortlessly with their Modular IP65 VIO-W221-MX100H Touchscreen Monitor. Enhanced Processing Capability for Complex Machine Vision Algorithms

Equipped with a 9th Gen Intel® Core™ i7-9700TE processor and an Nvidia Quadro RTX A4000 GPU, the VCO-6000 series provides the robust processing power required to efficiently handle the demands of sophisticated machine vision tasks. This high-performance setup ensures swift processing of extensive datasets and supports advanced image and video analysis, crucial for accurate defect detection and quality control on the production line.

Advanced Connectivity and Robust Storage Capabilities for Factory Assembly Line Operations

The VCO-6000 series enhances factory assembly line operations with its advanced connectivity and robust storage capabilities. Featuring a 10GB Ethernet card with dual Intel® GbE that supports Wake-on-LAN and PXE, it facilitates fast, reliable data transfer and remote system management. Additionally, its four 2.5” SATA HDD bays with RAID configuration ensure ample storage and data redundancy, critical for maintaining continuous operation and preventing data loss during intensive machine vision tasks. This combination makes the VCO-6000 series an efficient and dependable solution for demanding industrial environments.

Seamless Machine Vision Software Integration

The rugged IP65 Industrial Touch Panel VIO Monitor, with its full touchscreen capabilities, facilitated seamless integration of the machine vision software, enhancing the HMI experience. Its modular design allowed it to pair perfectly with the VCO-6000 series using the MX100H module, transforming the VIO panel into a fully functional, rugged monitor with extended I/O capabilities.

C&T's VCO-6000 series now supports 14th Gen Intel® Core™ processors with PCIe Gen 4 expansions and dual FHFL (Full-Height Full-Length) GPU configurations. Explore VCO-6000-RPL.

Also, explore our modular IP65 VIO-200 series with Display Modules: PC100-EHL.

The Benefits

The solution empowered the customer to run advanced machine vision software effectively, connect real-time high-speed cameras to minimize manufacturing errors, and reduce power consumption with a dual 120W power supply system for both the VIO Panel Monitor and other applications. Additionally, the secure integration of the VCO-6000 series and the VIO-W221-MX100H into their systems ensured stability and safety in their operational environment.

This partnership has not only resolved current operational challenges but also set the stage for ongoing support and collaboration on future projects, illustrating a successful integration of cutting-edge technology with practical industrial needs. Through this strategic alliance, the AI software vision company has significantly enhanced its production quality and efficiency, paving the way for future innovations in machine vision technology.