Shock and Vibration Test: Military Standard vs IEC Standard

When creating equipment for tough environments, it’s important to make sure it can handle physical stress and keep working reliably. This is why shock and vibration testing is so important. These tests help ensure that products can survive the conditions they’ll face, whether in military operations or industrial settings.

Two well-known standards for these tests are the Military Standard (MIL-STD) and the International Electrotechnical Commission (IEC) Standard. Both are used to test how products handle shocks and vibrations, but they are designed for different industries and have unique testing methods.

In this blog, we’ll explain the key differences between these two standards, how they test for shocks and vibrations, and which one might be the best fit for your needs. Whether you’re looking for military-grade toughness or industrial compliance, this guide will help you understand the essentials.

Table of Contents:

- What are Military and IEC Standards?

- Key Differences Between MIL-STD and IEC Standards

- Shock and Vibration Test Methods: MIL-STD-810 vs IEC 60068

- Pros and Cons of MIL-STD and IEC Standards

- Which Standard Should You Use?

- C&T's Products Tested for MIL-STD-810 and IEC Standard Compliance

What are Military and IEC Standards?

Understanding Military Standards (MIL-STD)

The Military Standard (MIL-STD) is a set of guidelines developed by the U.S. Department of Defense to ensure equipment performs reliably in extreme conditions. One of the most commonly used is MIL-STD-810, which focuses on testing how products handle environmental stresses like shock, vibration, extreme temperatures, and humidity. For example, a rugged computer tested under MIL-STD-810 might undergo vibration testing to ensure it works flawlessly inside a military vehicle driving over rough terrain.

Understanding IEC Standards

The International Electrotechnical Commission (IEC) creates standards for electrical and electronic equipment to ensure safe and consistent performance in industrial and commercial settings. The IEC 60068 series focuses on environmental testing, including shock and vibration. For example, an industrial panel PC tested under IEC 60068 may go through vibration tests to confirm its reliability when mounted on heavy machinery in a factory.

Key Differences Between MIL-STD and IEC Standards

While both MIL-STD and IEC Standards focus on testing how equipment performs under physical stress, their approaches and intended applications are quite different. Here's a table comparing the differences:

| Aspect | MIL-STD | IEC Standards |

|---|---|---|

| Purpose | Military-grade durability | Industrial and commercial reliablity |

| Testing Environment | Harsh, extreme environments | Controlled industrial environments |

| Customization | Flexible, tailored to application | Standardized, globally consistent |

| Applications | Defense, aerospace, ruggedized systems | Industrial automation, transportation, railway, electronics |

Shock and Vibration Test Methods: MIL-STD-810 vs IEC 60068

| Test | MIL-STD-810 Test Methods | IEC 60068 Test Methods |

|---|---|---|

| Vibration | Method 514 | IEC 60068-2-6 |

| Shock | Method 516 | IEC 60068-2-27 |

| High and Low Temperature | Method 501/502 | IEC 60068-2-14 |

| Humidity | Method 507 | IEC 60068-2-30 |

| Thermal Shock | Method 503 | Covered in IEC 60068-2-14 |

| Drop Test | Method 516 | IEC 60068-2-31 |

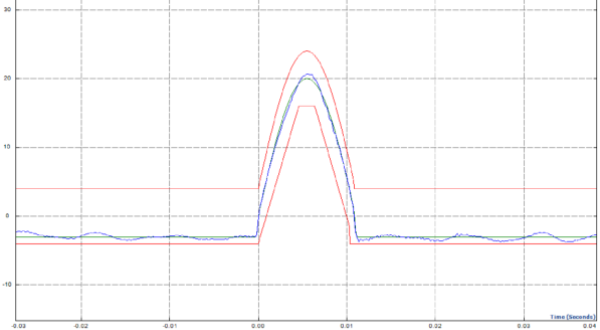

IEC60068-2-27 Test Procedure Result (Shock)

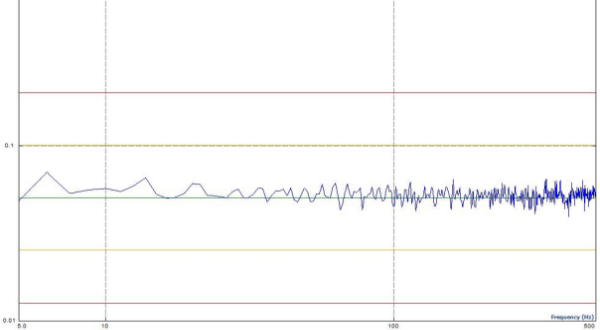

IEC60068-2-64 Test Procedure Result (Vibration)

Pros and Cons of MIL-STD and IEC Standards

When deciding between MIL-STD and IEC standards, it's important to understand their strengths and weaknesses.

| Pros | Cons | |

|---|---|---|

| MIL-STD | - High Durability: Designed for extreme environments like combat zones - Flexible Testing: Customizable to match real-world applications |

- Complex Testing: Requires expert knowledge and detailed setup - Higher costs: More expensive due to rigorous and flexible testing methods |

| IEC Standard | - Cost-Effective: Simpler and more affordable to conduct - Global Consistency: Widely accepted, ensuring international compliance |

- Limited for Extreme Conditions: Less suitable for harsh environments - Less Customization: Follows fixed guidelines, not tailored to specific scenarios |

Which Standard Should You Use?

Go with MIL-STD if your product will face extreme conditions, like in military, aerospace, or rugged industrial applications. Choose IEC if you need cost-effective, globally recognized testing for industrial, transportation, or commercial environments.

Real-World Examples for MIL-STD and IEC Standards

MIL-STD: A rugged computer mounted on a military vehicle must endure constant vibrations and sudden shocks from rough terrain.

IEC: A railway signaling system must handle vibrations from train movement and shocks during installation or maintenance.

C&T's Products Tested for MIL-STD-810 and IEC Standard Compliance

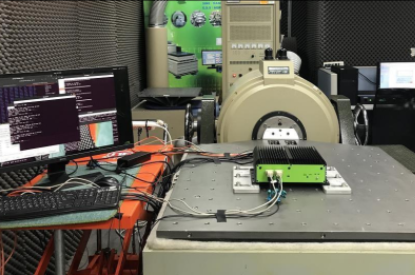

At C&T Solution, all our rugged computers are rigorously tested and certified to meet both MIL-STD-810G/H and IEC 60068 standards, ensuring reliable performance in the toughest environments, from military operations to harsh industrial and transportation applications. With our in-house advanced testing lab, we simulate real-world conditions, including heavy vibrations, sudden shocks, and environmental stresses, to guarantee durability and quality. Trusted in industries like aerospace, transportation, and automation, our rugged computers are customizable to fit specific needs while complying with global standards for both military and industrial use.

C&T Solution's In-House Testing Lab for Shock & Vibration

-

Shock & Vibration Testing

-

Package Drop Test

-

Thermal Shock Ramp Chamber

Explore our products or Contact us to consult with our rugged tech experts.

FAQ

- What are Military Standards?

Military Standards (MIL-STD) are guidelines created by the U.S. Department of Defense to ensure equipment performs reliably in extreme military environments, including combat zones and harsh conditions.

- What are IEC Standards?

IEC Standards are internationally recognized guidelines for testing the durability and reliability of electrical and electronic equipment, commonly used in industrial and transportation applications.

- What is the Military Standard for Shock and Vibration?

MIL-STD-810 is the primary standard for testing shock and vibration, using Method 514 for vibration and Method 516 for shock, simulating real-world military scenarios.

- What is the IEC Standard for Shock and Vibration?

IEC 60068 is the key standard for shock and vibration testing, including IEC 60068-2-27 for shock and IEC 60068-2-6 for vibration, focusing on industrial and transportation conditions.

- What is MIL-STD-810?

MIL-STD-810 is a military testing standard that evaluates equipment under environmental stresses like vibration, shock, temperature, and humidity to ensure durability in extreme environments.

- What is IEC 60068?

IEC 60068 is a standard for environmental testing, including shock and vibration, to assess product reliability during transport and operation in industrial settings.