Streamline Your Industrial Operations: Integrating SCADA with Rugged Edge Computers

Table of contents:

- Understanding SCADA Systems

- The Impact of Rugged Edge Computing

- Boosting SCADA with Rugged Edge AI

- How SCADA Systems and Edge Computing Collaborate

- Examples of SCADA Systems for Industry 4.0 Markets

- SCADA Hardware Solution: Rugged Edge Computers from C&T

In today's industrial world, using the right technology is key to staying ahead. SCADA (Supervisory Control and Data Acquisition) systems combined with rugged edge computers provide a powerful solution for businesses looking to enhance their automation and data management. These systems are designed to handle tough industrial environments and can manage data and processes efficiently, making them ideal for companies aiming to improve their operations through technology.

Understanding SCADA Systems

SCADA systems are crucial for overseeing and managing industrial activities. They work by collecting data from various sensors and devices spread across your operations.

This real-time data gives a clear picture of how things are running, helping you make better decisions quickly. Here are the main benefits of using a robust SCADA system:

- Manage and monitor processes from any location, whether nearby or remote.

- Use edge AI to gather and analyze data quickly, helping you see what's happening in real time.

- Improve awareness of your operations with detailed, up-to-the-minute data from your industrial sensors.

- Set up automated responses for specific events, analyze data trends, or create detailed reports easily.

Modern SCADA systems are now smarter, with better technology that processes data faster and connects more reliably, thanks to new machine learning capabilities. These systems are increasingly using edge computing, meaning data is processed right where it's collected rather than being sent to a distant server. This setup reduces delays and improves the reliability of data management, making it a top choice for industrial companies that need dependable, quick technology solutions.

Learn more about SCADA system.

The Impact of Rugged Edge Computing

Rugged edge computing places computing power and data storage close to where they are needed, enhancing speed and reducing the need for extensive data transmission in tough environments. By handling data right at the source rather than relying entirely on remote cloud servers, industries benefit from quicker data handling, lower delays, and better security. Rugged edge AI involves using artificial intelligence on strong, robust computers that are built to endure the harsh conditions of industrial sites. These systems are resistant to extreme temperatures, shaking, dust, and water, providing dependable operations even in difficult settings. These rugged computing solutions not only process data in real time but also integrate seamlessly with SCADA software, creating a centralized system for industrial operations to gather, monitor, analyze, and display critical data effectively.

Boosting SCADA with Rugged Edge AI

Rugged Edge AI involves running artificial intelligence algorithms directly on edge devices located close to where data is generated, rather than on distant cloud servers. When integrated with SCADA systems, rugged Edge AI offers several key benefits:

Real-Time Processing

Edge AI allows for immediate analysis and decision-making directly where the data is collected, significantly reducing delays that occur with cloud processing. This is essential for SCADA systems that depend on up-to-the-minute data for effective monitoring and control.

Increased Efficiency

By handling data on-site, Edge AI decreases the need for extensive data transmission to central servers, which is especially useful for industrial sites with limited connectivity or those located in remote areas.

Stronger Security

Processing data locally on edge devices helps to lower the risk of data breaches and cyber threats, adding an additional layer of security to sensitive SCADA operations.

Predictive Maintenance

Edge AI uses data from sensors and equipment to foresee possible breakdowns and maintenance requirements, minimizing equipment downtime and enhancing maintenance planning.

Advanced Analytics

With the capability to conduct sophisticated analytics and machine learning directly on the edge, Edge AI provides deeper insights into how operations are running, supporting more informed and strategic decision-making.

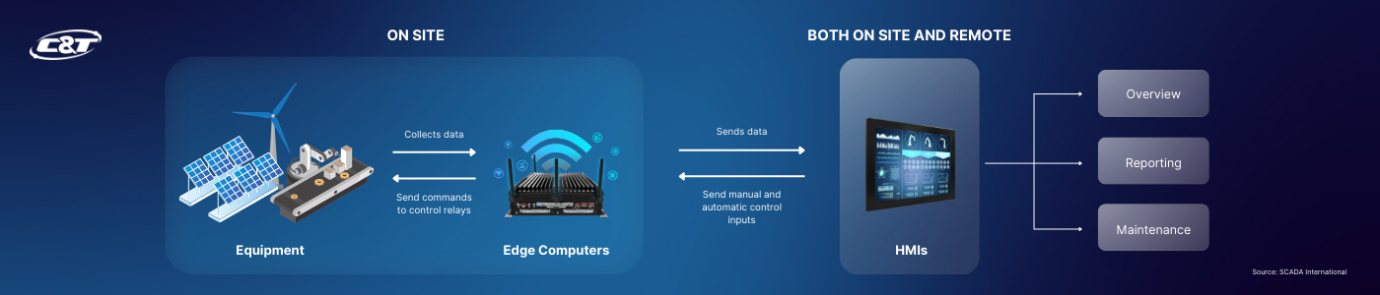

How SCADA Systems and Edge Computing Collaborate

Traditionally, SCADA systems depend on centralized data centers, which can cause delays and bandwidth problems. Edge computing solves these issues by processing data near its origin. This closeness cuts down on delay, improves data security, and makes bandwidth usage more efficient. For instance, in a manufacturing setting, sensors gather information about machine performance, environmental factors, and production levels. This information is then processed in real-time by an edge computer. The SCADA software visualizes this data, allowing operators to track performance, identify issues, and make decisions swiftly.

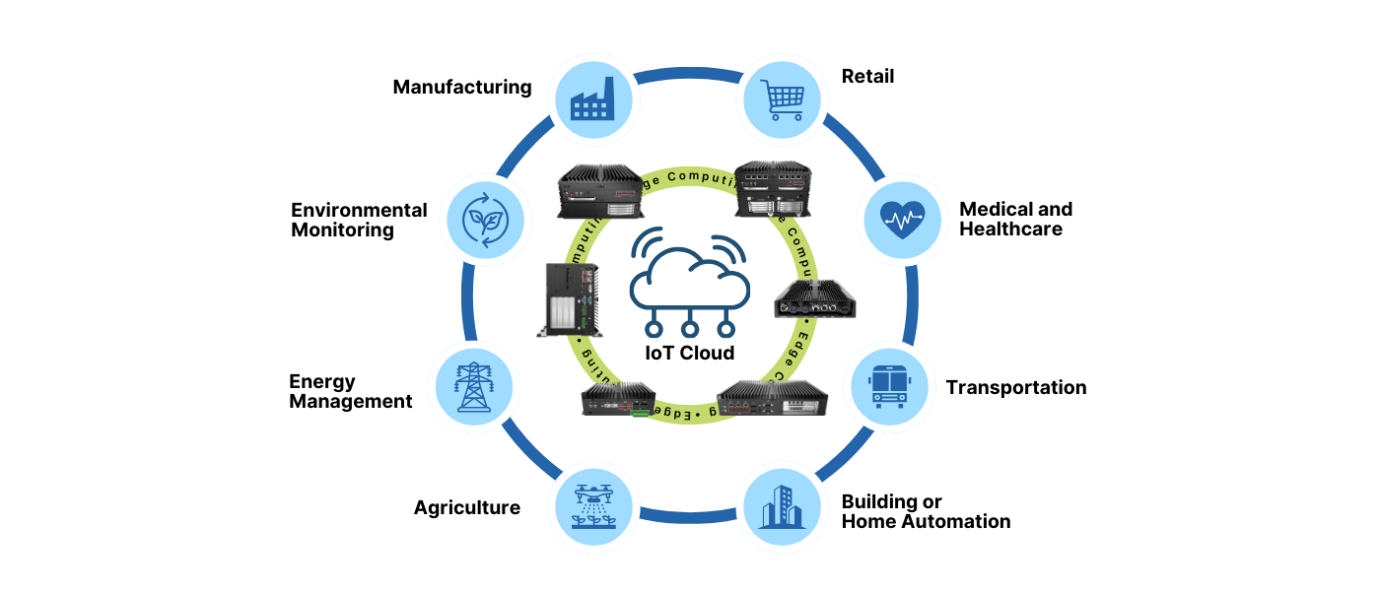

Examples of SCADA Systems for Industry 4.0 Markets

► Manufacturing

SCADA systems in manufacturing monitor machines and production data in real-time, reducing downtime and improving quality and resource use. Automation allows quick adaptation to demand changes, saving costs and increasing output.

► Energy

In energy, SCADA systems monitor power generation, transmission, and distribution, ensuring reliable supply. They prevent outages, manage energy loads, and integrate renewables by providing real-time system data.

► Water Treatment

Water treatment facilities use SCADA to monitor purification and distribution, ensuring water quality. SCADA tracks parameters like pH and turbidity, automates wastewater treatment, and helps maintain compliance with environmental standards.

► Oil and Gas

SCADA systems in oil and gas provide real-time data on pipelines and equipment, enhancing efficiency and safety. They enable remote monitoring, reduce on-site personnel needs, and support predictive maintenance to prevent downtimes.

► Transportation

SCADA in transportation manages traffic signals, rail operations, and logistics, improving flow and safety. They monitor vehicle movements and infrastructure, optimize train schedules and logistics, and reduce costs.

► Agriculture

SCADA systems in agriculture control irrigation and monitor crops and livestock. They automate watering based on soil moisture, conserve water, increase yields, and ensure optimal conditions in greenhouses and livestock facilities.

SCADA systems are crucial across various industries, enhancing operational efficiency, reducing downtime, and improving decision-making through real-time data collection, processing, and control.

SCADA Hardware Solution: Rugged Edge Computers from C&T

C&T offers top-tier rugged edge computers designed to thrive in tough industrial settings. Here are the key benefits of C&T's rugged computing solutions, which can serve as gateways for data collection and analysis in SCADA systems:

Rugged Durability

C&T's edge computers are built to function in extreme conditions, including high temperatures, dust, and vibrations. This durability ensures consistent performance in challenging industrial environments.

Real-time Data Processing

Equipped with powerful processors and advanced computing features, C&T edge computers can manage real-time data processing at the edge. This is essential for SCADA systems that need immediate data analysis and quick responses.

Scalability and Flexibility

C&T provides a variety of edge computing solutions that can be customized to fit the specific needs of different industries. Whether you need a compact unit for small operations or a robust system for large industrial facilities, C&T has the right solution.

Enhanced Security

By processing data locally, C&T edge computers minimize the risk of data breaches and cyber-attacks, utilizing hardware encryption with TPM and secure boot technologies. This local data processing adds an extra layer of security, which is crucial for industries handling sensitive information.

Seamless Integration with SCADA Software

C&T edge computers are designed to integrate smoothly with leading SCADA software, ensuring efficient and effective operation.

In the era of Industry 4.0, combining SCADA systems with edge computing is changing how industries operate. C&T's Edge Computers provide the ruggedness, real-time processing, and smooth integration needed to get the most out of SCADA software.

Contact us to consult with our industrial technical experts.