Enhancing Fire Detection with SFF Industrial Computer for Emergency Response Solutions

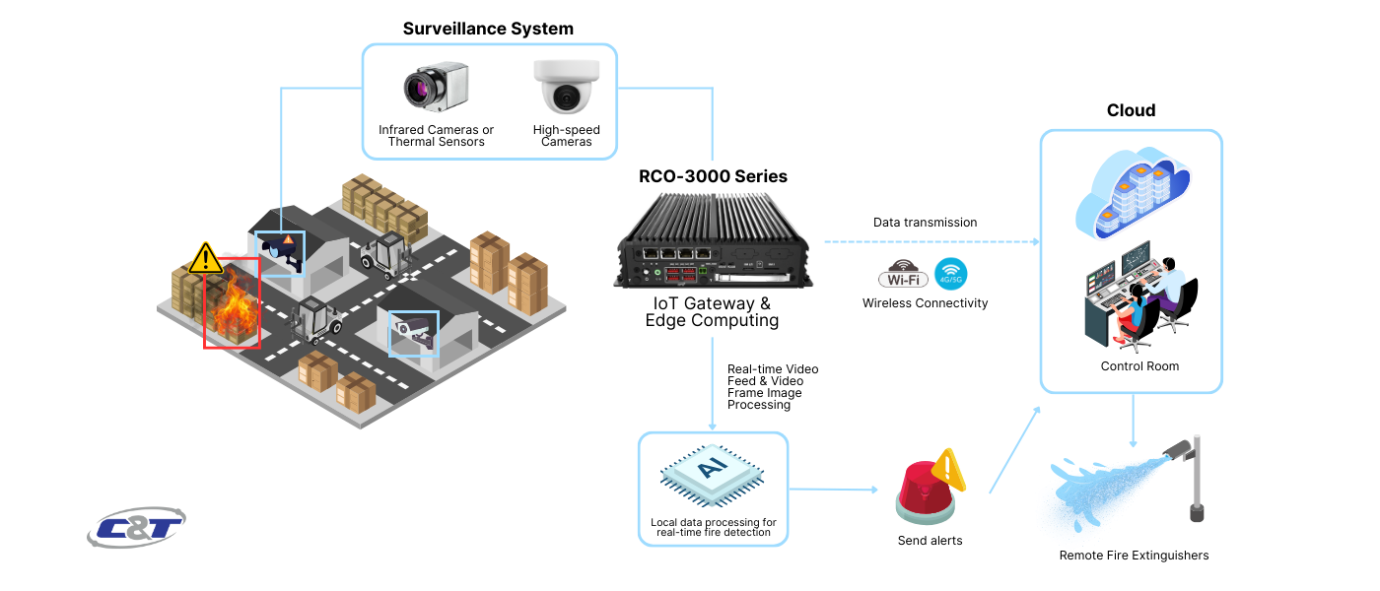

Fire detection and suppression systems are essential in high-risk industrial environments, using advanced tools like thermal imaging, AI-driven analysis, and remote monitoring to detect fires early and respond quickly. To operate effectively, these systems need a dependable, high-performance computing platform. In this case study, we look at how C&T’s RCO-3000-CML small form factor industrial computer helped a major fire detection and suppression company overcome challenges by offering a strong, flexible, and compliant solution for continuous operation in tough conditions. This example highlights how edge computing and IoT are applied in Disaster & Emergency Management.

Challenge:

- A durable edge computing solution with extensive I/O connectivity for sensors, cameras, and other peripherals.

- Flexible mounting options suitable for industrial environments.

- A compact, high-performance system.

- Fanless and reliable industrial computers designed for continuous operation in harsh conditions.

- Wireless connectivity for fast, low-latency communication.

Solution:

- C&T’s RCO-3000 Series Small Form Factor Computer (RCO-3000-CML).

- Extensive I/O options with 6x USB 3.2 Gen 2 (10 Gbps) ports and 8 digital I/O ports for sensors and cameras.

- Compact design powered by Intel Core i7 for high-performance tasks.

- Dual SSD support with a removable 2.5" SATA HDD bay (hot-swappable).

- Flexible mounting options with vertical and horizontal capabilities for industrial setups.

- Wide operating temperature range and UL certification for industrial-grade durability.

- 4G/LTE, 5G, and Wi-Fi 6E wireless connectivity for fast, low-latency communication.

Benefits:

- Ready-to-use rugged edge computing solution.

- Streamlined lead time management.

- Manufactured in an ISO-certified facility for quality assurance.

Company Background

Founded in 2015, this fire detection and suppression company has quickly become a leader in delivering advanced solutions for high-risk industrial environments. Their key products, such as the continuous suppression system and portable fire extinguishers, are built to provide rapid and effective fire detection and control. A standout feature is their virtual firefighter technology, which enables real-time monitoring and remote action, ensuring quick responses to fire threats. The company is known for integrating customizable fire protection systems across different sectors, including industrial, commercial, and remote areas. Their commitment to meeting strict safety standards and their focus on innovation have established them as a trusted partner in fire safety.

The Challenge

Rugged Edge Computing Solution with High I/O Connectivity for Sensors and Cameras

The fire detection company needed an edge computing system that could easily connect to various devices like sensors, cameras, and other monitoring tools. For example, in a warehouse, thermal sensors could detect rising temperatures or smoke and send signals through I/O ports. The system would process this data in real-time, triggering cameras to capture images and alerting virtual firefighters. To make this happen, they needed a solution that could handle high data input and output from multiple devices reliably.

Flexible Mounting Options for Vertical and Horizontal Orientations

Since the company's products are used in many different places, from indoor spaces like offices to outdoor locations such as construction sites, they needed a computing system that could be mounted in different ways, both vertically and horizontally. Many traditional systems lacked this flexibility, which caused inefficiencies. The company required a system that could adapt to various installation needs without losing performance or stability.

Compact Form Factor with High-Performance Capabilities

Space was limited in many industrial setups, so the company needed a compact but powerful computing solution. In crowded environments, equipment is often packed tightly together, leaving little room for additional devices. Even with limited space, the system needed to offer high processing power to handle large amounts of data from fire detection sensors and cameras. A small yet powerful system was essential to process data efficiently while fitting into tight spaces.

Reliability and Certification for Continuous Operation in Harsh Environments

The company needed a rugged computer that could run continuously in tough industrial conditions. The environments often had extreme temperatures, dust, vibrations, and other harsh factors. The system had to be strong enough to work in these challenging conditions and certified for long-term use without needing constant maintenance or repairs. Without this reliability, system failures could occur, leading to downtime that would jeopardize safety and operations.

Wireless Connectivity for Low-Latency Communication

In fire detection, fast communication between sensors and the edge computing system is crucial. Wireless connections like 4G/LTE and 5G allow sensors to send data instantly, avoiding the need for complicated wiring setups. On large industrial sites or in remote areas, fast wireless connections ensure that important data is sent quickly, allowing for immediate response. The company needed a computing solution with advanced wireless modules to ensure stable, low-latency communication between machines.

The Solution

After carefully analyzing the fire detection and suppression company's needs, C&T’s RCO-3000-CML Small Form Factor Computer was chosen as the ideal solution. This system is designed to operate reliably in harsh environments, ensuring continuous performance. Its compact design, combined with support for 10th Gen Intel® processors, provides the necessary power for handling complex fire detection tasks. The RCO-3000-CML is also highly adaptable, making it easy to integrate into various industrial setups for real-time data processing. Its rugged construction, low maintenance requirements, and compatibility with mission-critical systems make it perfect for high-risk fire safety operations.

Rich I/O Connectivity for Sensors and Cameras

The RCO-3000-CML provides a wide range of I/O ports, perfectly suited to the fire detection system's need for integrating multiple devices. It includes 6x USB 3.2 Gen 2 ports for fast data transfer and 8 isolated I/O DIO ports for connecting sensors and cameras. These ports enable smooth, real-time data capture and communication with virtual firefighters, ensuring fast response times. Additional connectivity features include 3x RS-232/422/485 ports for industrial communication, 2x CAN Bus for vehicle systems, dual LAN ports (RJ45), 1x Line-out for audio, and a Universal I/O Bracket. This diverse I/O setup enhances the system’s flexibility for use in different environments.

Compact Size with High-Performance Intel Core i7

Despite its small form, the RCO-3000-CML supports powerful 10th Gen Intel® processors. To meet the specific needs of the fire detection company, it comes with the Intel Core i7 processor, which delivers the performance needed to process large amounts of data in real-time. This ensures the system can manage the fire detection devices efficiently, while still fitting into space-limited industrial environments.

C&T's RCO-3000 series now supports 14th Gen Intel® Core™ processors. Explore RCO-3000-RPL.

Dual SSDs with Hot-Swappable SATA HDD

The RCO-3000-CML features dual SSDs along with a hot-swappable 2.5" SATA HDD bay, allowing the company to separate the operating system from data storage. This improves system reliability and ensures the fire detection software runs uninterrupted while efficiently storing data. The hot-swappable feature enables easy replacement of storage drives without downtime, which is essential in critical environments where continuous operation is crucial for safety.

Flexible Wall Mounting for Industrial Setups

The RCO-3000-CML's flexible wall mounting options allow for easy installation in a variety of industrial environments, from construction sites to large warehouses. The system can be mounted both vertically and horizontally, making it versatile enough to fit into even the most challenging spaces without sacrificing performance or durability.

Wide Operating Temperature Range and Industrial Certifications

With an operating temperature range of -25°C to 70°C and UL certification, the RCO-3000-CML is built to withstand extreme environmental conditions. This rugged design is crucial for the fire detection company, as their systems are often deployed in tough environments like dusty industrial sites or outdoor locations with extreme temperatures. The UL certification ensures reliable operation in these settings, minimizing maintenance needs and ensuring continuous protection.

4G/LTE, 5G, and Wi-Fi 6E Wireless Connectivity for Low-Latency Communication

The RCO-3000-CML provides robust wireless connectivity through its M.2 B Key slot, supporting 4G/LTE and 5G modules, and an M.2 E Key slot for Wi-Fi 6E. Wi-Fi 6E offers faster speeds, better network efficiency, and lower latency, making it ideal for demanding environments. This ensures real-time communication between sensors and edge computing systems, allowing fast and efficient responses without relying on complex wired setups.

The Benefits

Standard Off-the-Shelf Rugged Edge Computing Portfolio

C&T’s RCO Series, which includes the RCO-6000, RCO-3000, and RCO-1000 models, offers ready-made, rugged computing solutions designed for various industrial needs. Each model is optimized for specific use cases, allowing businesses to quickly implement reliable and durable systems without long waiting times. Whether used in tight spaces or complex edge environments, the modular and scalable design of the portfolio provides flexibility while maintaining high-performance levels. This reduces time-to-market and ensures real-time data processing for seamless operations.

Efficient Lead Time Management

C&T’s strong focus on demand forecasting and supply chain management ensured short lead times, even during disruptions caused by the pandemic. This allowed the fire detection company to avoid delays in deploying their safety systems, keeping critical operations on schedule without interruptions.

ISO-Certified Facility

C&T’s manufacturing process is ISO-certified, ensuring that their products meet strict industry standards for quality and reliability. This gives the fire detection company confidence that the hardware used in their safety systems is durable, dependable, and compliant with global standards.