Dust and Water Resistance: Breaking Down IP67, IP68, and IP69K Standards

In electronics and industrial equipment, understanding the level of protection a device has against environmental factors like dust and water is crucial. This is where IP (Ingress Protection) ratings come in. This blog will delve into the specifics of IP67, IP68, and IP69 ratings, highlighting their differences and applications.

What is an IP Rating?

An IP rating, which stands for Ingress Protection rating, is a standard used to define the levels of electrical enclosures against intrusion from solid and liquid objects. This rating system is internationally recognized and is defined by the International Electrotechnical Commission (IEC).

What do the numbers in an IP Rating stand for?

The IP rating consists of two digits:

- First Digit (Protection against solids): The first digit signifies the degree of protection an enclosure provides against solid objects, ranging from 0 to 6. A "0" denotes no protection, whereas numbers 1 through 6 represent progressively higher levels of defense, from protecting against large body parts to fine dust particles.

- Second digit (Protection against liquids): The second digit reflects the extent of protection an enclosure provides against liquids, which span from 0 to 9K. A value of "0" means no protection, while digits 1 to 9K indicate an enclosure's protection against liquids, primarily water.

What are the differences between IP67 vs IP68 vs IP69K Ratings?

| IP Rating Level | IP67 | IP68 | IP69K |

| Advantages | Protected against temporary immersion in water (up to 1m depth for 30 mins). Suitable for most consumer electronic devices. Generally, more affordable than higher IP ratings. | Protected against full water immersion beyond 1m up to 30 mins (duration can extend specified by the manufacturer. More suitable for devices used in water-related activities. Higher water resistance than IP67 | Protected against high-pressure water steam-jet. Capable of withstanding close-range high-temperature washdowns. Suitable for applications that require harsh washdowns. |

| Disadvantages | Limited to short-term water immersion. Not suitable for prolonged or deep-water exposure. May does not protect against high-pressure water jets. | IP68 is not for high-pressure water applications and may experience water ingress with prolonged submersion | IP69K is not designed for prolonged underwater use and typically requires more complex and costly enclosure designs |

What are the applications of IP67 vs IP68 vs IP69K?

IP67 Applications

- Consumer Electronics: Smartphones, cameras, and wearable devices that require protection against dust and temporary immersion in water.

- Outdoor Electrical Equipment: Lighting fixtures and outdoor enclosures that need to be dust-tight and withstand rain or temporary flooding.

- Automotive Components: Sensors and electrical components in vehicles that are exposed to dust and water, especially in off-road or adverse weather conditions.

- Industrial Equipment: Machinery and tools used in dusty environments or occasionally exposed to water.

IP68 Applications

- Advanced Consumer Electronics: High-end smartphones and devices designed for extended underwater use, such as waterproof cameras.

- Marine Equipment: Devices used in marine environments, like underwater lighting and marine-grade connectors, that can endure prolonged submersion.

- Outdoor and Underground Installations: Electrical enclosures and junction boxes that are buried or exposed to prolonged wet conditions.

- Specialized Industrial Applications: Equipment used in wet processes or that may be submerged as part of their operational environment, such as certain types of pumps and valves.

IP69K Applications

- Food Processing Equipment: Machinery that requires regular, high-pressure, hot water cleaning to meet hygiene standards.

- Pharmaceutical Manufacturing: Equipment that needs to withstand stringent cleaning protocols involving high-pressure steam and water jets.

- Heavy-Duty Vehicle Components: Parts used in construction, agriculture, or mining vehicles that are regularly exposed to high-pressure water for cleaning.

- Industrial Washdown Applications: Equipment in environments where high-pressure, high-temperature water is used for cleaning and decontamination.

In conclusion, understanding the distinctions between IP67, IP68, and IP69K ratings is crucial for selecting the right equipment for specific environments and applications. While IP67 offers solid protection against dust and temporary water immersion, making it ideal for general consumer electronics, IP68 extends this protection to prolonged water immersion, suited for devices used in wetter, more demanding environments. On the other hand, IP69K is designed for high-pressure, high-temperature water jets, catering to industries that require rigorous cleaning processes. Each rating serves a unique purpose, and the choice depends on the level of exposure to dust and water that the device will encounter. By carefully considering these ratings, you can ensure that you select the most appropriate, durable, and reliable equipment for your needs, whether it's for everyday use or for specialized industrial applications.

C&T's IP67/IP69K Rated Computing Solutions

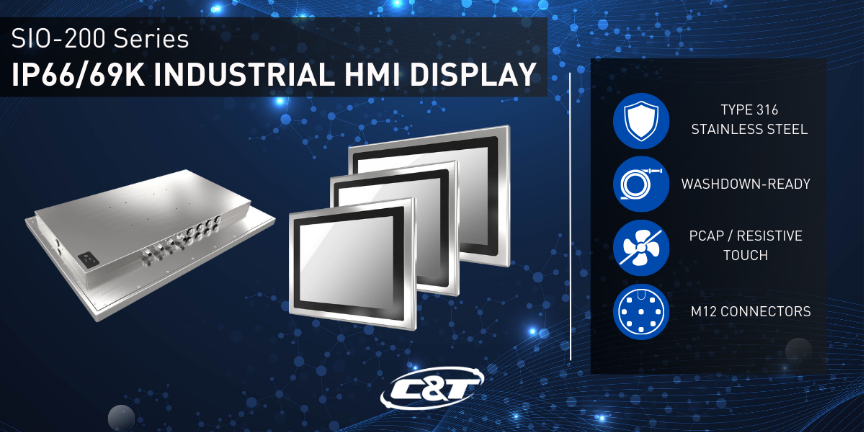

SIO-200 Series Washdown Touchscreen Computer

The stainless-steel SIO Series, slim and IP69K-rated, offers powerful processing and connectivity for Industry 4.0 modernization. It's engineered for easy cleaning, delivering precise data, responsive interaction, and scalable integration in cleanrooms and aseptic settings, perfectly fitting into highly hygienic environments.

WCO-3400 Series Fanless Embedded Computer

The WCO-3400, a fanless embedded system, boasts a robust IP67-rated enclosure, ensuring exceptional dust and water resistance. This design and customizable I/O make it ideal for mission-critical applications in various demanding industrial environments.