AI Vision Stadium Lighting: Transforming Stadium Lighting with Industrial GPU Computers

Challenge:

- Lacked the right industrial computing solution to support their AI-powered lighting system for sports events.

- Required a system that could connect various IoT devices, such as cameras, sensors, and lighting equipment.

- The solution had to be tough enough to work in outdoor cabinets exposed to extreme weather.

- Required PoE (Power-over-Ethernet) support to power multiple cameras, sensors, and lights.

- The solution needed to meet safety standards for easy certification.

Solution:

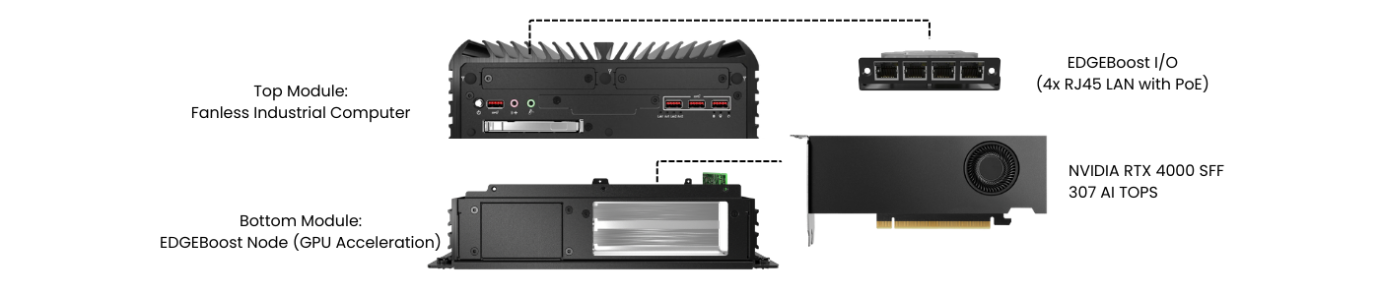

- C&T’s RCO-6000-RPL Series AI Edge Inference Computer, featuring a 13th Gen Intel Core TE processor, DDR5 memory, and NVIDIA RTX 4000 SFF.

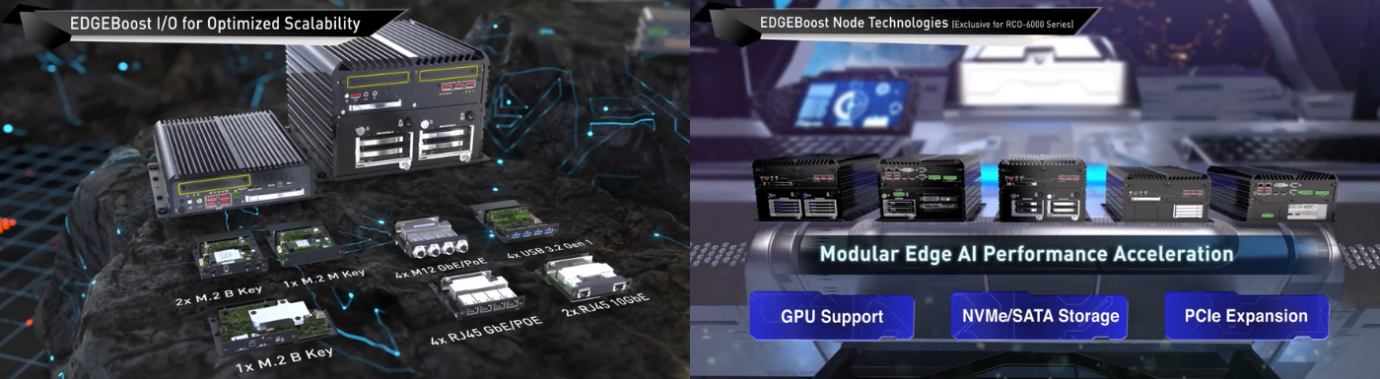

- Modular EDGEBoost Node technology to enhance GPU performance and PCIe Gen 4 speed.

- Modular EDGEBoost I/O technology for extra PoE-enabled RJ45 LAN ports.

- Built for harsh conditions with a fanless and cable-free design.

- Certified to top safety standards (CE, FCC, UL) for full compliance.

Benefits:

- Provided a complete edge computing solution with customized BIOS, OS imaging, and tailored shipping handled in-house.

- Capable of high-volume production and fast delivery to meet tight deadlines.

- C&T’s engineering and sales teams ensured expert support to meet customer needs.

- Strong communication between C&T and the solution provider, ensuring a smooth project

Company Background

A global leader in creating advanced lighting solutions for sports, transportation, and infrastructure, this company has been innovating for over 40 years. They specialize in stadium lighting, offering features like special effects, optimized LED technologies, and better experiences for athletes and spectators. With the rise of AI, they plan to use AI vision to improve the stadium lighting experience. To make this possible, they needed a powerful, industrial-grade computing solution.

The Challenge

After discussions with C&T, several key challenges were identified that posed major obstacles for the lighting solutions manufacturer. These challenges included limitations on installation locations and ensuring the compatibility of IoT devices. Let’s take a closer look at each of these issues and explore the pain points in detail.

Challenges of Implementing AI Vision at the Edge

AI has become a game-changer in technology, and this leading lighting manufacturer saw its potential to transform stadium lighting systems. After successful internal testing, the company was ready to move to the next step: piloting their AI-powered solution in real-world scenarios. However, they faced a critical challenge: finding a reliable, industrial-grade edge computer to run their demanding vision software.

Initially, they considered cloud computing, which offers abundant processing power in data centers. However, they quickly realized that cloud computing wasn’t a viable solution. The high costs of data bandwidth, the need for stable connectivity (especially during large stadium events with thousands of connected devices), and latency issues made it unsuitable for their needs. Cloud computing couldn’t provide the real-time responsiveness needed for their AI system.

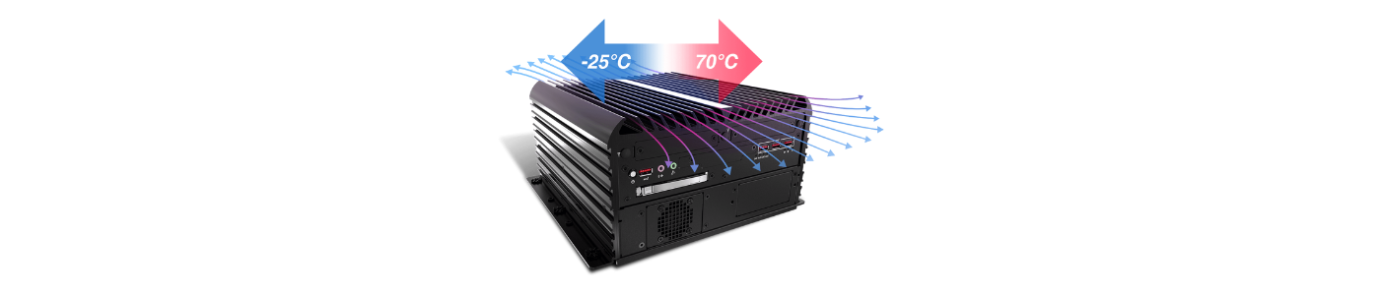

Edge computing, on the other hand, was essential for the AI vision lighting system, which required instant processing to detect, track, and adjust lighting in real time. The demanding AI application needed GPU acceleration to process large amounts of detailed data quickly and accurately. However, integrating a GPU-powered industrial computing solution isn’t simple. It comes with challenges such as managing heat, space limitations, and the need for continuous operation in harsh outdoor conditions.

Ensuring Compatibility with High-Quality PoE Vision Cameras

The manufacturer also needed to integrate multiple high-specification Power over Ethernet (PoE) vision cameras. These advanced cameras were crucial for capturing high-resolution footage of key elements such as players, the ball, and field markings. PoE technology was critical for simplifying the system, allowing data and power to travel over a single cable. This approach reduced clutter and ensured reliable connections for the high-quality data needed to adjust the lighting in real time.

Deployment Challenges in Stadium Lighting

Stadium light poles are designed with a 15-foot-high driver-control cabinet to house essential electronics and prevent tampering. These cabinets are outdoors and exposed to harsh weather, so the internal components need to be rugged enough to function in extreme conditions. The challenge is that these control cabinets are small and lack ventilation, so the edge computing solution not only has to handle intensive AI workloads but must also fit within the limited space and remain operational in varying weather conditions.

In addition, the edge computing solution had to meet UL certification standards. Achieving this certification was critical for ensuring the system met safety requirements and helped streamline the overall certification process.

The Solution: RCO-6000-RPL AI Edge Inference Computer

C&T recognized the challenges faced by the stadium lighting manufacturer and recommended the RCO-6000-RPL Series AI Edge Inference Computer to kick off their pilot project.

Powerful Industrial GPU Computers for AI Vision Workloads

The AI vision technology for stadium lighting required significant processing power to handle real-time AI tasks. To meet these demands, a dedicated GPU was crucial for fast AI processing and reliable performance. C&T’s RCO-6000-RPL Series was designed with powerful edge AI components to deliver the necessary computational power.

This industrial-grade computer features a 13th Gen Intel Core TE processor, DDR5 RAM, and NVMe storage for fast data handling. It seamlessly supports an NVIDIA RTX A4000 SFF Ada GPU with 307 TOPS of AI tensor performance, which was essential for running the AI-powered stadium lighting system efficiently. The modular design of the RCO-6000-RPL Series ensures flexibility and scalability for future upgrades.

EDGEBoost I/O Technology for Seamless Camera Integration

In addition to its AI capabilities, the manufacturer needed support for multiple PoE (Power-over-Ethernet) vision cameras, which are critical for streaming data used in AI processing. Powering and processing data from several cameras at once posed a challenge.

The RCO-6000-RPL Series addressed this need with EDGEBoost I/O technology. This module enabled seamless IoT connectivity, allowing for easy integration of vision cameras and ensuring reliable data transmission. The RCO-6000-RPL was equipped with an EDGEBoost I/O module featuring four RJ45 LAN ports with PoE, making it easy to connect the cameras and other devices required for AI-driven lighting adjustments.

Reliability for Rugged Stadium Lighting Environments

The manufacturer needed to fit the components into a driver-control cabinet mounted 15 feet above the ground on the stadium light pole. This required a solution that was compact yet durable enough to withstand extreme weather conditions.

The RCO-6000-RPL Series met these requirements with a fanless, cableless design that enhances ruggedness by preventing dust and debris from entering the system. This design also supports wide temperature ranges, wide power input ranges, and has built-in power protection, making it reliable in tough environments. It is also resistant to shock and vibration, ensuring that it can perform reliably even in harsh conditions.

Internally, the RCO-6000-RPL Series is built for long-term, consistent operation. It uses an Intel Core TE processor with 35W TDP for energy efficiency, while also benefiting from Intel’s 10-year embedded product support to ensure long-term consistency. The NVIDIA RTX 4000 SFF Ada GPU offers high-performance AI processing with low power consumption (70W TDP), making it a perfect fit for a rugged, energy-efficient system.

With its combination of robust design and advanced internal components, the RCO-6000-RPL Series delivers the performance and durability required to power AI-based stadium lighting systems in even the toughest environments.

The Benefits

C&T, a leader in edge computing, provides valuable benefits to strengthen long-term partnerships with OEMs, system integrators, and Industry 4.0 businesses.

Tailored Edge Computing Solutions for Different Stadium Needs

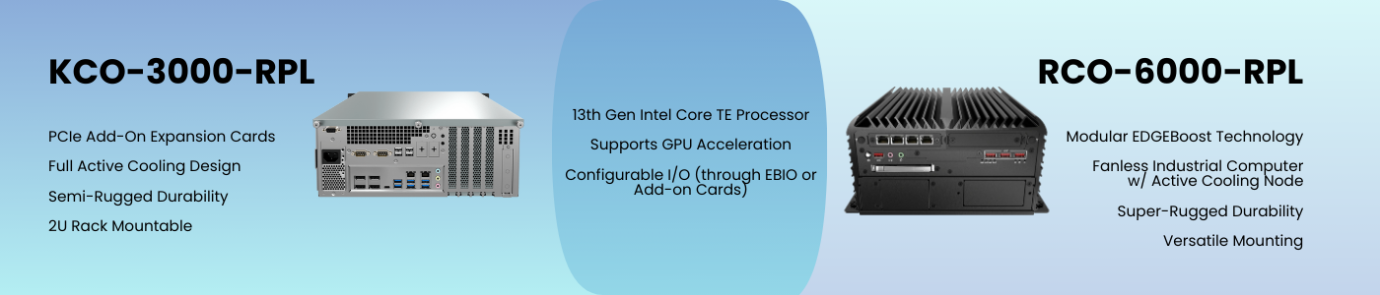

The stadium lighting manufacturer, after selecting the rugged RCO-6000-RPL Series, needed to expand their edge computing options for various stadium environments. To meet this need, C&T offered the more cost-effective KCO-3000-RPL Series Fanned Industrial Computer. Both series feature the same processor, memory, and GPU acceleration, ensuring consistent edge AI performance for a range of AI vision applications.

While the RCO-6000 Series is designed for extreme outdoor conditions, the KCO-3000 Series is perfect for demanding industrial environments. This flexibility allows the manufacturer to deploy the RCO-6000 in tougher outdoor stadiums and the KCO-3000 in less harsh settings, optimizing their AI vision system for each specific location.

End-to-End Manufacturing Support

C&T supported the manufacturer by providing complete in-house manufacturing services. This included fine-tuning BIOS settings and installing their custom OS images, eliminating integration issues. Additionally, C&T’s rigorous burn-in testing ensured the system’s reliability. The result was a fully configured, plug-and-play AI Edge Inference Computer, ready for immediate installation. This approach helped the manufacturer avoid lengthy technical setup, speeding up deployment and reducing resource usage.

Personalized Engineering and Sales Support

C&T’s dedicated engineering and sales teams worked closely with the stadium lighting manufacturer throughout the project. This hands-on approach ensured a clear understanding of the project’s needs and helped minimize lead times. The strong collaboration between the teams helped deliver fast, effective solutions, fostering a partnership built for long-term success.

Scalable Production and Warehouse Capabilities

C&T’s facility in Taiwan, allowed them to scale production and fulfill high-volume orders quickly. This capability was essential for the manufacturer, enabling them to meet current deployment needs while supporting future expansion of their AI vision lighting system without delays.

Contact us to consult with our industrial technical experts.