How To Build A Fanless PC? 6 Steps of Building a Fanless PC

One essential design factor that determines how well a computer performs is its cooling design. When deciding which thermal design to implement when building a computer, air cooling, water cooling, and passive cooling are the best-known cooling method. Either of these methods can effectively cool down the computer's component that generates the most heat, the central processing unit (CPU). Air, water, and passive cooling each have their own benefits and downsides. However, passive cooling or fanless design is known to be the best PC cooling solution for applications that require rugged, robust, and compact features.

Fanless PC is excellent for industrial applications, space-constrained solutions, power-efficient systems, and many more. Compared to the other two, building a PC with a fanless design allows the system to do much more in terms of versatility, durability, reliability , flexibility, and longevity. That said, in this blog, we will provide you with an essential guide on how to build a fanless PC.

6 Steps of Building a Fanless PC

Step 1: Choose the right CPU

Before building a fanless PC, first, you need to figure out what kind of CPUs fit the requirements of your specific application. Choosing the right CPU will help you design a better fanless system when implementing passive cooling.

When choosing a CPU for building your fanless PC, you need to be aware of three things. They are TDP, T-Junction, and Thermal Throttling.

TDP or thermal design power: is the value representing the CPU's power consumption and heat output when running some applications. TDP is measured in Watts, and it shows how much power is consumed by the CPU. Since heat is the byproduct of energy, TDP also represents the amount of heat is generated by the CPU without passing its thermal limits.

T-Junction or Tj: is a term that represents the temperature that is measured right on the CPU silicon chip. At the same time, Max T-Junction is the highest temperature the CPU can reach before it starts to thermal throttle.

Thermal Throttling: this is when the CPU reduces its power and performance to avoid excessive overheating. The CPU will try to cool down itself and stay within the normal operating temperature by reducing its processing frequencies.

That being said, there is a wide range of CPUs with different TDP available for building a fanless PC. Typically, in the processor market, the CPUs can range from 10W to 130W of TDP, depending on their performance level. Building a fanless PC is all about the balance between performance and wattage. For instance, getting a 95W CPU will allow your computer to run highly demanding programs but with the trade-off of requiring active cooling to cool the system. In contrast, for making a fanless PC, you want to get a CPU ranging from 10W to 65W of TDP. Any CPU with more than 65W of TDP will require active cooling to maintain reliable performance.

Understands CPUs TDP, and their differences between GPUs and TPUs

Step 2: Replacing HDDs with SSDs

Another component to consider when building a fanless PC is a storage solution. Since traditional HDDs (hard disk drives) are built with multiple moving parts and potential failure points, it's better to switch them with SSDs (solid-state drives). SSDs are much more durable, compact, faster, and power-efficient compared to HDDs. Therefore, implementing SSDs will make your fanless PC more solid-state. Eliminating fans and HDDs reduces the computer's failure points, translating to much better durability and reliability.

Learn more about the differences between HDDs and SSDs | Which one's better?

Step 3: Utilize Ultra-conductive Heatsinks

The third step of building a fanless PC is utilizing ultra-conductive heatsinks for more efficient heat dissipation. The essence of fanless design is how to passively cool the internal heat by dissipating the heat from the CPU to the outer enclosure of the computer. Heatsinks are the bridges between the heat-generating processors and the chassis. Therefore, heatsinks need to be ultra-conductive. The heatsinks ultra-conductive materials such as aluminum and copper heat pipes ensure the computer can dissipate heat efficiently from the heat-generating processors to the fanless PC case. In addition, for a better thermal design, some fanless computers install additional heatsinks on the other high-heat processors, such as PCH (platform controller hub) or additional modules and accelerators. Also,don't forget to apply thermal paste or thermal pads between the heatsinks, processors, and chassis for optimal heat conductivity.

Learn more about CPUs, heatsinks, and their cooling solutions

Step 4: Fanless PC Case

Fanless PC's case is the last stop for the heat that travels from the CPU and heatsink before it dissipates to the surrounding airflow. The case structure of a fanless PC is different compared to fan-cooled desktops. Fan-cooled computer cases are usually made of plastic and thin aluminum plates with a smooth surface. In comparison, fanless PCs take case designs to another level. Fanless PC cases are incredibly rugged, made out of extruded aluminum with heavy-duty metal. For example, C&T's fanless computer cases are extruded into one-piece chassis with built-in copper heat pipes that deliver durability and efficient heat dissipation. The one-piece design eliminates moving parts and allows the fanless PC to become truly solid-state. Moreover,fanless pc cases have dedicated heatsink fins on their surface that provide the case with a wider surface area. With heatsink fins and more surface area, the fanless PC cases can dissipate heat to the surrounding airflow as much and as quickly as possible.

Learn more about fanless PC case and vibration resistant computers

Step 5: Put Everything Together

After you've chosen the right CPU, SSDs, heatsinks, and case for the fanless PC, the last step is to put everything together for a completely fanless computer. The main advantages of fanless systems are the ability to withstand shocks and vibrations. Fanless PCs are more than just durable, compact, and low power. Fanless PCs are also very quiet. Without fans, fanless PCs are airtight and much smaller compared to standard desktop computers. Even though not every application needs a fanless PC, having a fanless design on your PC architecture offers a myriad of benefits compared to fan-cooled computers.

Step 6: Environmental Testing and Validation

The sixth step of building a fanless PC is to ensure the system is truly robust, durable, and reliable. After designing and building a fanless PC, the overall system design needs to go through rigorous testing and validation processes to diagnose the success or failure amid industrial environments. These specialized tests push the computer to extremes, often to a point of destruction. In testing and validation, the destruction of the product is a great indication of its overall design but most importantly, its limitations. If manufactures do not test to extremes, the overall reliability or mean time between failure (MTBF) of a computer may be below industrial-grade standards. As a result, more industrial computing manufactures invest into capital testing equipment in order to test and validate designs in a variety of environmental settings .

However, for individuals doing a DIY fanless PC, attempting to test and validate their system properly can be very expensive. Moreover, some PC manufacturers also do not have the capital to test their hardware directly and require a third-party testing lab to run the test. This is due to the incredibly high capital cost to establish a private testing lab for industrial hardware. However, it's hard to monitor the processes on a third-party testing lab closely. As a result, the quality controls might not meet the desired standard when not examined firsthand.

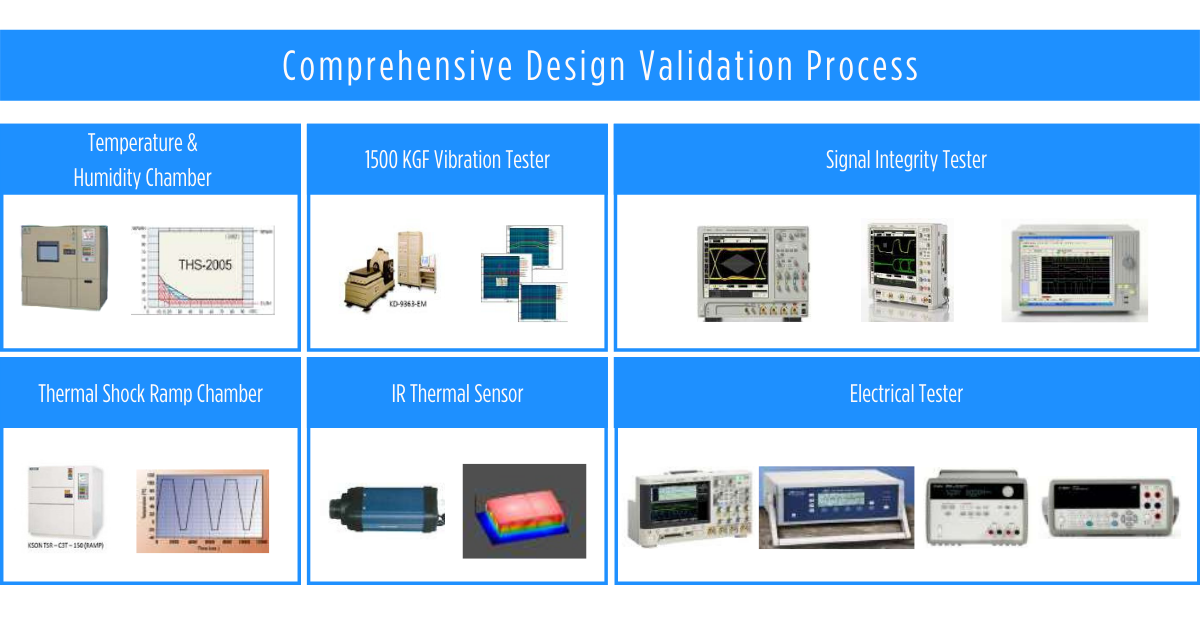

Therefore, C&T has built an in-house testing lab for comprehensive testing and validation processes to ensure the reliability of our fanless industrial computers in real-world deployments. This is a mandatory step to ensure C&T's fanless industrial PCs endure embedded durability, reliability, and longevity. C&T's in-house labs are built with specialized testing equipment to imitate real-life situations and test the hardware to its limit. Some of this in-house testing equipment include temperature & humidity chambers, thermal shock chamber; multi-axis shock and vibration tables; IR thermal sensors; EMI signal integrity; and pre-certification procedures for regulatory compliance agencies.

These tests included:

- Compliance test: Electromagnetic compatibility (EMC) test for EC and FCC certifications.

- Signal Measurement: Signal integrity for high-speed peripherals to ensure best design attributes.

- Stress Test: Observe result when operating beyond the normal standard or meeting maximum specification.

- Functional Test: Basic I/O functional test, boot up test, OS, power protection, power consumption, performance test, full loading test.

- BIOS setup test: To ensure the system properly detects, configures settings, and initializes all functions and devices.

- Compatibility test: To ensure CPUs, DIMMs, display card, and other peripherals are compatible with the system.

- Environmental Test: Thermal test including four corners, operating and non-operating, booting test, shock & vibration test, sealing for IP rating, and thermal shock test

Quick Summary of Fanless PC Benefits:

- Silent Operation

- Shock and vibration resistance

- Dust and debris resistance

- Higher reliability and durability

- Small footprint

- Environment operability

- Low power consumption

Learn more about the benefits of fanless PCs

Frequently Asked Questions (FAQs)

Can you make a Fanless PC?Yes, it is possible to make your own fanless PC. Some of the components you'll need for building a fanless PC are a 10W to 65W TDP CPU, ultra-conductive heatsinks, and a purpose-built fanless PC case.

Is a fanless PC good?

Fanless PCs offer a wide array of benefits such as compact size, higher durability, low maintenance, longer MTBF (mean time between failure), power efficiency, shock and vibration resistance, dust resistance, silent operation, and much more.

How do you make a fanless mini PC?

You can make a fanless mini PC by incorporating SBC (single board computers) for a smaller form factor that utilizes an SoC (system on chip) on the computing architecture. Some of these SoCs have integrated memory and GPU. Thus, you can have a smaller footprint while still maintaining the power and fanless design.

How do fanless computers keep cool?

Fanless computers stay cool by naturally dissipating the heat conducted from the CPU to the external enclosure. The heat conducted to the case will be cooled by the air flowing passing the computer. Hence, passively cooled the system without any fans.

DIY or Premade Fanless PCs?

A fanless PC may have fewer components than an air-cooled or water-cooled computer, but fanless design can be challenging to ensure it works effectively and reliably. Thankfully, you can experiment with building your own fanless PC, or you can save the hustle and buy a premade one. At C&T, our engineers have designed fanless cooling solutions for more than 30 years in the United States. In addition, C&T fanless computers are purpose-built, tested, and validated for the most extreme industrial deployments. As a result, you have the chance to save more time, energy, and expenses to build reliable and robust fanless systems. Contact Us to learn more about fanless industrial solutions and how to get one.