12.May.2023

How Are Rugged Computers Made? Part 1: Shock and Vibration Testing

Industrial computers are expected to maintain functionality and connectivity within remote and harsh environments. Unfortunately, these locations are unpredictable as they may be outdoors, exposed to variable weather conditions, and even in enclosed areas that may experience strong t urbulence. These conditions may cause systems to fail, resulting in business interruptions and lost revenue for organizations. To avoid this risk, manufacturers must guarantee their products can continue to operate without failure and subject them to tests. Shock and vibration testing is one way to ensure a product's reliability.

Keep reading to learn about shock and vibration testing types, procedures, machinery, and some real-life scenarios where industrial computers may be exposed to shock and vibrations.

What is Shock and Vibration Testing?

Shock and vibration testing is essential as it recreates the environments industrial computers will be deployed in to ensure they can withstand the stresses of real-world settings. Shock and vibration testing is one of many environmental testing procedures manufacturers conduct, such as humidity, temperature , etc. These tests expose the products' vulnerabilities to accurately predict their operational capabilities. Through this process, manufacturers can continue to improve product design and ensure their computers can withstand harsh industrial environments on the hardware side. Although not control all variables can be controlled for, at least we can eliminate the chances of failure due to hardware design.

Sinusoidal and Random Vibration Testing

There are two common types of vibration testing. The first kind is sine vibration testing, where the computer is subjected to a vibration of one frequency. The second type is called random vibration testing, where the product experiences vibrations of multiple frequencies. Sine testing helps to identify resonances in a product, whereas random vibration testing simulates more of a real-world setting.

Gpk is the measurement unit for Sine testing, and Grms is the unit of measurement for random vibration acceleration. During the test, the product is secured to a shaker table, driven by a signal generator that produces the required vibration. Typically, industrial computers are tested for a range between 3-5 Grms.

Shock Testing

Manufacturers also subject their products to shock testing, where they experience high acceleration levels to test products sustainable to experiencing similar acceleration levels during their real-world applications. For example, products that may experience high levels of impact are tested for shock, like industrial computers.

A kind of shock test is the classical shock test, where the product is subjected to a series of rapid changes in acceleration. G is the unit used to measure shock acceleration. During the trial, the product is secured to a shock table, and a striker or pneumatic ram is used to deliver the required shopping. Typical shock test requirements can range from 50G, depending on the purpose of the product. For example, for industrial computers, shock tests are typically tested for 50G.

C&T are dedicated to providing the best quality computers tested for the harshest conditions.

From Left to Right: Curtis Ho, Ives Tsao

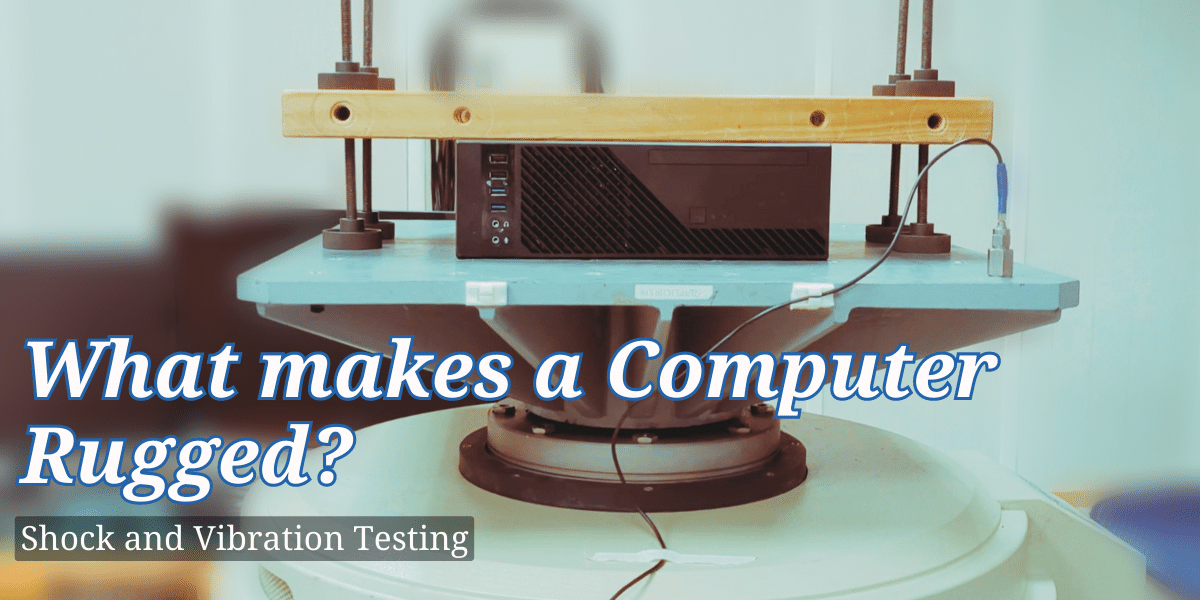

At C&T, we use King Design's shock and vibration machine, capable of testing all our machines and technology to comply with international shock and vibration standards and certifications.

In-house Shock and Vibration Testing

At C&T, we have in-house machines that conduct shock and vibration tests for all our industrial computers. Our engine can apply up to 500g of shock acceleration and 3 Grms of random vibration acceleration to a product. Our in-house operators are above, standing beside our shock and vibration machine. The machine consists of a vibration head, which generates the vibration, and a control unit, which manages the vibration test. The vibration head is attached to a shaker table, driven by a signal generator that produces the required vibration. The control unit operates the signal generator, shaker table, and the sensors that measure the product's response to the vibration.

Shock and Vibration Test Procedure

The first step in the test procedure is to prepare the product for testing. This involves mounting the product on the shaker or shock table and securing it. Once the product is secured, the test procedure can begin. The machine is programmed to apply the desired acceleration and vibration, and the test is run for a specified period. During the trial, the sensors measure the product's response to the conditions, and the data is recorded for analysis. If the product passes the test, it can be certified as reliable for use in Industrial Environments. Conversely, if the product fails the test, the design can be modified to import its durability and reliability.

The video below shows a demonstration of one of C&T's industrial computers being subjected to a Random Vibration Test of 3GRMS.

Real-life Application Examples

Many industries, including marine and railway, conduct shock and vibration testing for their products. Within marine applications, industrial computers must withstand harsh ocean conditions. Vibration and shock testing are undertaken to ensure systems can withstand the impact of high waves and strong winds. railway applications, industrial computers must withstand the vibration and shock caused by trains traveling at high speeds. Therefore, vibration and shock tests are critical in environmental tests to ensure systems can withstand extreme conditions while operating reliably.

Certification Compliant

Several certifications are available for products that demonstrate their reliability in industrial environments. These certifications include EN50155 and EN50121-3-2 for railway applications, MIL-STD-810H for standard military applications, specifically MIL-STD-81 0H 514.8 for vibration testing, and MIL-STD-810H 513.8 for shock testing. These certifications ensure the functionality of a product in harsher environments beyond that in which typical consumer products can operate.

Find out more about EN50155 Railway Certification Here

Find out more about Mil-Spec Computers Here